Molecular Safe System

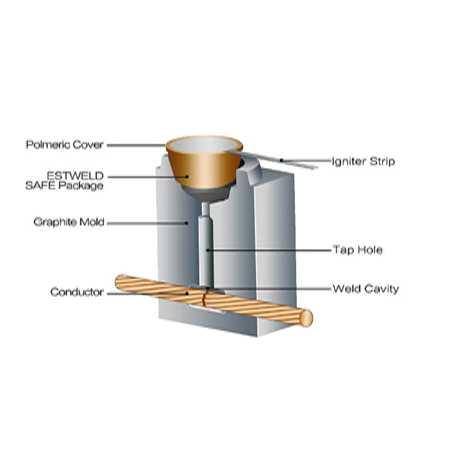

Continuing the tradition of technical leadership, ESTWELD® SAFE was developed as a simplified method of performing exothermically welded electrical connections.

This trusted system now features a new ESTWELD SAFE cup design for the integrated welding material package which has streamlined the installation process by eliminat- ing ignition materials.

The tamper proof, integrated welding material package consists of a copper cup containing ESTWELD® SAFE patented welding material alloys and an ignition source.

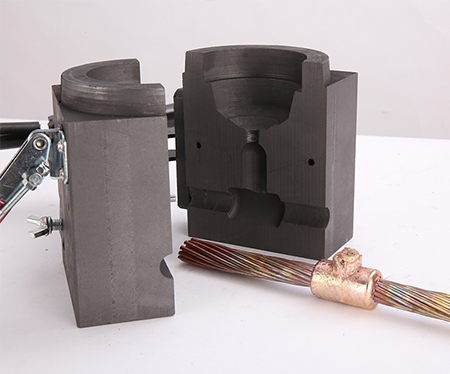

This newly shaped welding material package is designed for use in all standard ESTWELD® SAFE molds. Once placed in the ESTWELD® SAFE mold, the welding material is electronically ignited using a simple battery-powered control unit with a six-foot lead.

- Consists of a tamper proof, disposable moisture-resistant welding material cup. The welding material, disk and ignition source are incorporated into the self-contained package

- Long shelf life

- Completes welds at distances of up to 6 ft/1.8 meters (can be extended)

- Requires minimum components – no starting material, no disks, no flint igniters

- Easy to handle, store and transport – by air, land or sea in unlimited quantities

- Reduces installation time by 20%

- Has safety-certified electronic igniter is designed for 500 connections with one set of 8 standard AA batteries (included) – requiring no special batteries or chargers

- Designed for use in standard ESTWELD® SAFE molds

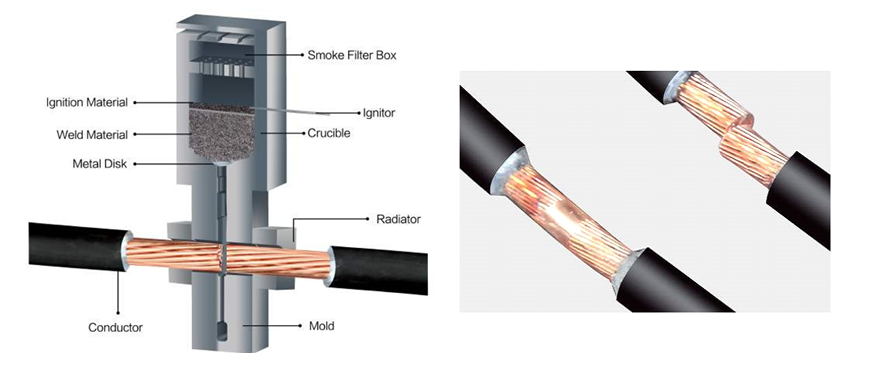

- Integrated Welding Material Package

- Electronic Control Unit

- Replaceable Six foot or lengthenable Control Unit Lead

- Smoke Filter Mold

- Simplifies training and set up

- Saves labor

- Simplifies cleaning

- No starting material required

- Easy ignition

- Increased flexibility in hard to reach areas

- Prevent sparks and produce minimal smoke

- Can be used in a specific place

- ESTWELD® SAFE high-voltage welding system can weld different sections copper cables.

- ESTWELD® SAFE connections can be made easily with minimal training.

- ESTWELD® SAFE weld is small –handling is simple after welding

- Specially designed weld profile for high-voltage applications.

- No external power or heat source required. Has a current carrying capacity equal to that of the conductor.

- Permanent molecular bond will not deteriorate with age, cannot loosen or corrode.

- Will withstand repeated faults, is made with lightweight equipment, has low labor cost and is time saving on jobsites.

-

Step 1

Insert ESTWELD® SAFE package into mold

-

Step 2

Attach control unit termination clip to ignition strip

-

Step 3

Press and hold control unit switch and wait for the ignition

-

Step 4

Open the mold and remove the finished connections.